Parts of an English Lever Pocket Watch

All of the parts of an English lever pocket watch are shown here. That’s all there is; This is the fusee type so the spring in its drum turns the fusee which equalisises the torque. Each normal wheel drives a pinion, gradually gearing up the rotations. The centre wheel turns once in 60 minutes (minute hand) and the forth wheel rotates once in 1 minute (second hand).

From left to right, top, movement plates, and case. Next row, spring drum with cap, Balance wheel complete with hairspring and roller platform, dial and dust cover. Lower third of picture L to R, fusee and set-up ratchet wheel and click to pre-load the mainspring: The dial washer, canon pinion, hour wheel and minute wheel which all live under the dial: The fusee chain, centre wheel, third wheel, forth and escape wheels, and the escapement pallets (lever). Hands and assorted screws and tapered brass pins.

Normal procedure is to assemble front or dial side downwards.

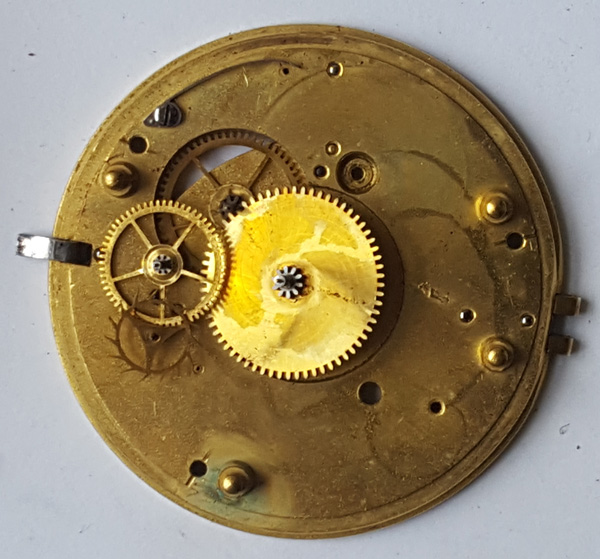

Four Basic wheels

This is the arrangement of the primary watch gearing.

The pinion in the centre of the solid centre wheel is driven by the fusee wheel.

The front support for the third wheel is recessed into a bridge.

The fourth wheel has an elongated front arbour that protrudes through the dial to carry the seonds hand.

The escape wheel is the last in the train of wheels; it rocks the lever to impart the impuls to the balance wheel.

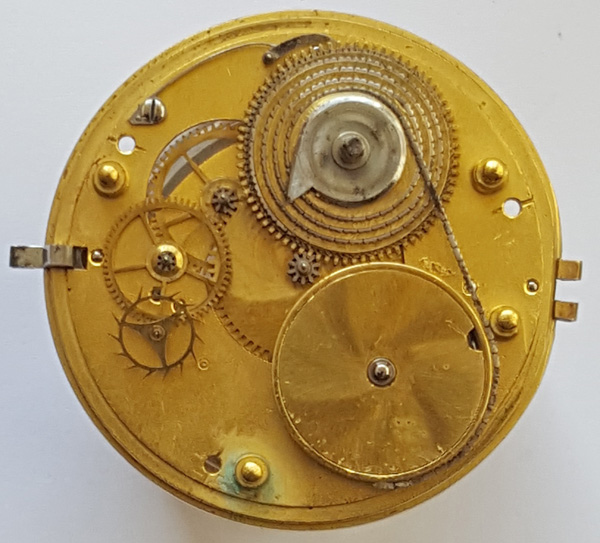

The fusee, chain and spring drum

The fusee is the most complicated part in this type of watch not only becauase of its complicated spiral scroll but also it contains the winding click and the “nose” above the cone of the fusee is the stop work which prevents over-winding.

The picture shows how the chain would appear in the fully wound position. For assembly, the fully unwound condition is easier.

Importantly, the small curved piece just above the top of the fusee wheel is the Harrison maintaining power detent: a slot in the underside of the fusee wheel allows the detent to apply driving force from its spring while the watch is being wound.

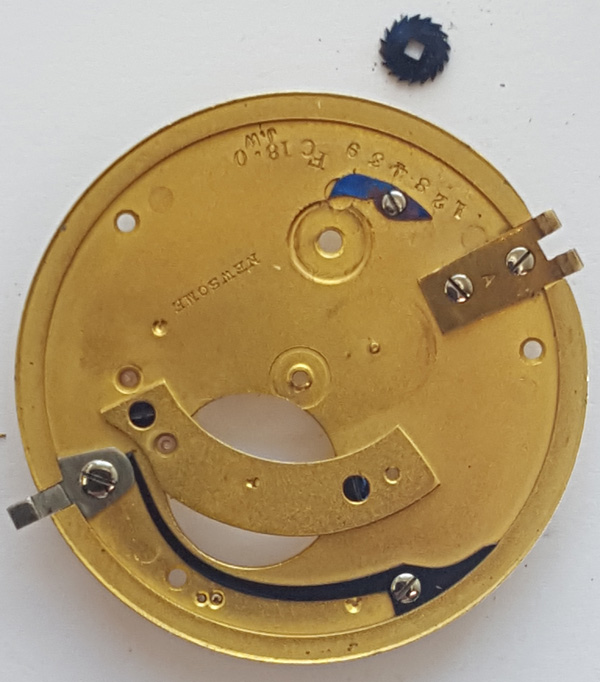

Some small but important details

Lightly grease or oil the mainspring and replace the spring drum cap firmly.

Before assembling everything that belongs between the plates, screw the set-up click to the dial side of the front plate. It can be quite fiddly to get the screw to line up so best done first rather than after.

The set-up ratchet wheel will be fitted later onto the square on the front of the spring drum arbor.

Now its just a matter of putting in the between the okates work.

Better to use a movement clamp for this part of the assembly – at least until the back plate is mostly on